School of STEM establishes Engineering Machine Shop in Innovation Hall

The University of Washington Bothell School of STEM received $300,000 in funding from the UW Bothell Worthington Technology Fund for mechanical engineering equipment used in instruction. This funding helped upgrade and establish the larger Engineering Machine Shop for engineering students in the School of STEM.

“We are so grateful to our donors and faculty who know how important it is for our engineering students to work on projects using industry-grade equipment so that they are workforce ready,” Vice Chancellor of Academic Affairs Sharon Jones said.

Located in Innovation Hall 015, the Engineering Machine Shop serves as a crucial resource for students in engineering and related fields.

“A machine shop is a vital organ of an engineering program,” Mechanical Engineering Lab Coordinator Jacob Roth said. “We envisioned a teaching shop that could accommodate up to 18 students at a time, and that’s exactly what we have now.”

The shop is split between instruction and student-driven work, serving as both a learning space and a hands-on workshop. Roth regularly assists students conducting research, building prototypes and completing capstone projects.

Expanding access to the machine shop

In prior years, Roth taught a three-hour hand-tools only course for students to experience some of the shop’s features. With the establishment of the new shop in Innovation Hall, he is planning to revitalize that workshop to expand opportunities in the space. Currently, access to the machine shop is limited to students who have completed the machining fundamentals course for the safety of both students and the equipment.

However, Roth hopes to make the entire shop more accessible to a broader range of students by expanding the machining fundamentals course to all students. Currently, it has mechanical engineering prerequisites, so it’s typically only engineers taking the class.

“It would be great if I could tell anyone and everyone, ‘take our intro to machining,’” Roth said.

A hub for innovation & collaboration

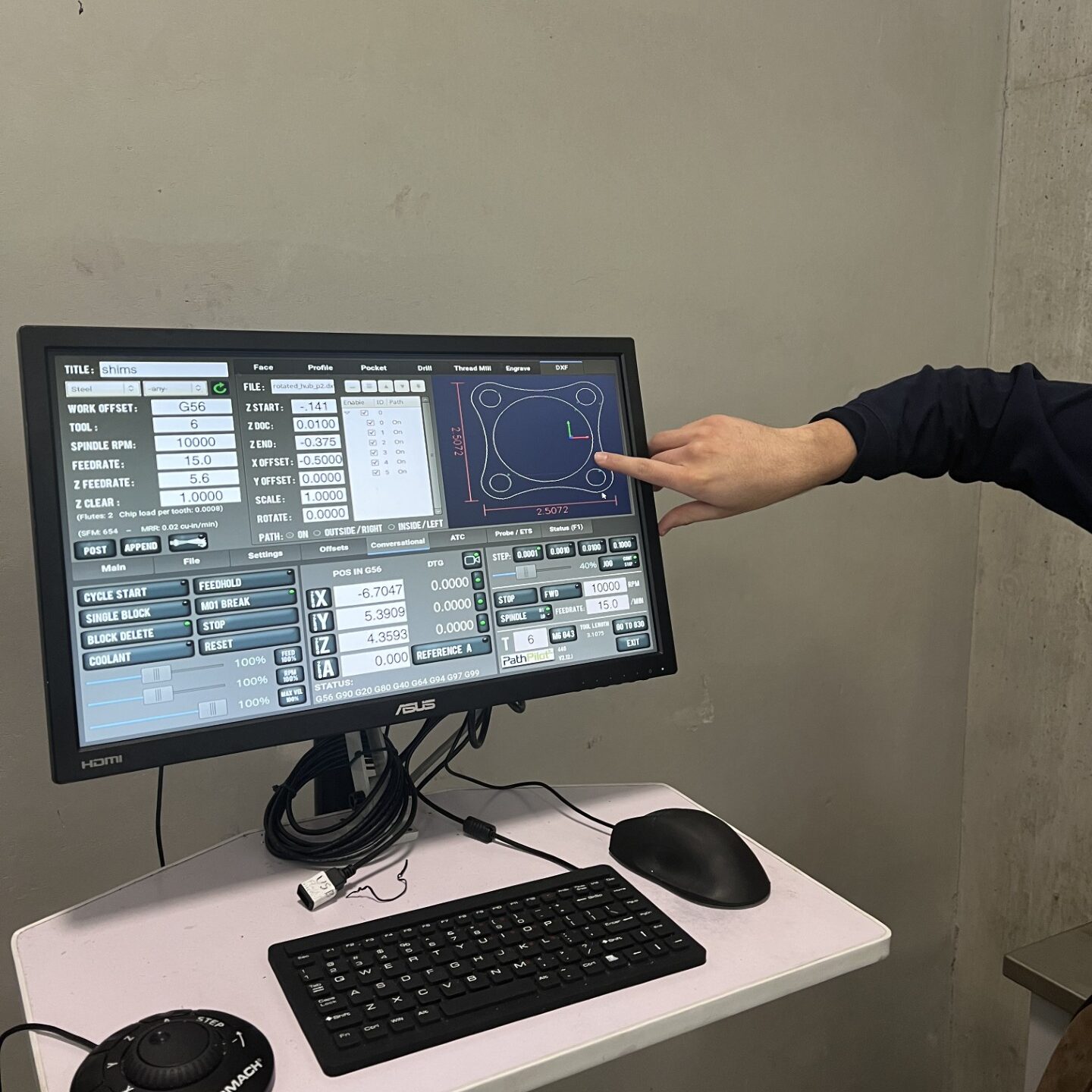

Access to the machine shop allows students to create custom metal parts on short notice and work one-on-one with Roth to refine designs in advanced software.

“For research students in non-engineering disciplines, who haven’t been trained on any machines, I’ll often work with them to produce engineering drawings and then I’ll make the part for them and give it to them,” Roth said.

Beyond coursework, the machine shop is also a hub for student clubs. Groups like the Electric Motorsports Club and the TrickFire Robotics Club frequently use the space, helping fund equipment purchases and maintenance through the Student Technology Fee.

Souri Banerjee, a mechanical engineering graduate from UW Bothell, ran into difficulties using the worn-down equipment in the previous machine shop. The parts he machined for his electric motorsport club wouldn’t turn out exactly as envisioned because the equipment was well used. He reached out to Roth about utilizing the student technology fee for additional equipment since a lot of student clubs used the space. After surveying other engineering clubs to see what equipment they needed for their projects, he and Roth worked together to submit a funding request which was approved.

“I wish we had that new equipment when we were students, because that would have made our tasks easier,” Banerjee said. “But I am so very glad that the students now and all future students are going to be able to experience machining.”

With the funding from the Worthington Fund and the Student Technology Fee, the UW Bothell Machine Shop is enhancing hands-on engineering education, supporting student innovation and fostering collaboration across STEM disciplines.

Available equipment

- Four lathes

- Three manual mills

- Grinder station including chop saw

- A vertical and horizontal bandsaw

- Drill press

- Two Computer Numerical Control (CNC) mills and a forthcoming CNC lathe