Students at the University of Washington Bothell who major in Mechanical Engineering are required to take a myriad of courses in science and math. From statistics to thermodynamics, these courses provide foundational knowledge and skills they will need to enter the field.

Students in Intro to 3D Modeling, Design and Analysis, for example, learn how to create 3D models. But in Capt. Bill Anderson’s version of the class, the curriculum takes things a step further by simulating a real-world scenario for how this skillset could be applied.

Over the course of five weeks, students are challenged to work in teams to design a product from start to finish. And as students learned, the biggest challenge isn’t designing a product itself. Rather, it is communicating with clients and manufacturers from outside the classroom to translate client needs into real-life products.

“I hope the students take away an entire library of skills about design, manufacturing, creativity, collaboration and the like, but most importantly is the requirement for great engineers to be great communicators,” said Anderson, a retired captain from the U.S. Navy and an associate teaching professor in the School of STEM.

“The greatest design of the millennium that is stuck in your head is of no use if you cannot communicate to others the specifications or how to manufacture the product.”

A mutually beneficial partnership

At the beginning of the project, students complete fundamental skills in drawing standards, computer aided design, product design and analysis, and the basics of project management. They then form small group “engineering consultancies” of two to three people and are introduced to a live “client” — a corporate volunteer representing a local manufacturing company based upon an amalgamation of similar real companies in the Pacific Northwest.

They’re also introduced to an “offshore” rapid prototyping manufacturer. Little do they know, the manufacturer is a similar team of students at Lake Washington Institute of Technology in Kirkland.

Collaboration between the two institutions began in 2019. Anderson said it’s a mutually beneficial partnership, with his students completing real work-specific engineering challenges, and their LWTech counterparts gaining hands-on experience for their courses in machining, fabrication and manufacturing.

“The UW Bothell Mechanical Engineering program had an early relationship with LWTech focused on helping create a more clear pathway for LWTech students to transfer to UW Bothell,” he said. “And one of the brainstorms was based on how we can create opportunities for students from both schools to interact with one another.

“This process ultimately led to the high impact teaching collaboration we use today.”

From start to finish

Students learned from the client that their project was to design a simple bracket to connect a seat back to a seat base for a yacht’s weather deck. The design and the rapid prototype, manufactured by the LWTech students, needed to be both functional for the desired purpose and optimized for mass production and installation.

For Nicole Yates, a junior majoring in Mechanical Engineering, the hands-on experience went well beyond simply learning how to use modeling software.

“This course greatly exceeded my expectations,” she said. “I didn’t know that we would gain valuable experience by designing a product from start to finish. It showed me that creating a model is only one small piece of designing a product as an engineer.”

As Anderson noted, “the students have to go through the full lifecycle of design” — from inception of the concept and identifying client needs and expectations to hand drawing designs and creating specifications to give to their manufacturer.

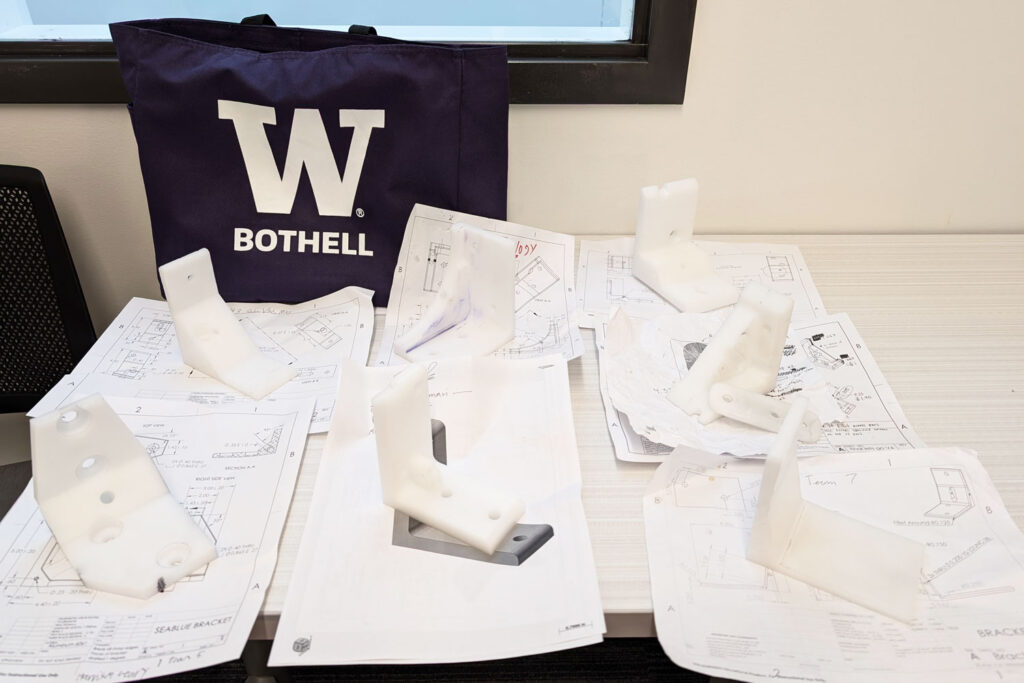

Students gave final presentations where they pitched their products in the hopes that the client would select their prototype. In addition to the physical prototype provided by their LWTech counterparts, they also presented on the materials, manufacturing costs, time and scaling needs, and beyond.

“A big takeaway from this class was that you can’t really have the engineering work without having to communicate and work with other people.”

Nicole Yates, junior, Mechanical Engineering

The best, simple solution

In the end, only one prototype could be selected by the client.

“The winning team design for this year focused on practicality and simplicity. Their product design met the client’s needs, and they met this goal by thinking out of the box — not constrained by self-biases in design — and keeping their solution as simple as possible,” Anderson said. “Most of the best engineering solutions in history were elegantly solved using the simplest concepts.”

It wasn’t just the simple design that stood out but also the team’s extraordinary communication skills.

“We all knew going in that communication is really what was going to make this project and what Captain Anderson was pushing us to do,” said Finn Richardson, a senior majoring in Mechanical Engineering who was on the winning team. “We discovered that sending the weekly updates to the client and then just consistently back and forth emailing with the manufacturer to really get those straight and being really on top of it definitely set us apart from others.”

For Richardson and her teammate Brooke Ojala — another senior in Mechanical Engineering — the project provided a closeup look at what they might expect in their future careers. Both said they are interested in pursuing engineering careers in biotechnology after graduation.

Prepared for future success

“A big takeaway from this class was that you can’t really have the engineering work without having to communicate and work with other people,” Ojala said. “You can’t just sit in a closet and crank away at math problems and just have people slide you things under the door.

“You have to actually have that business part of you, that consumer-facing part in your job,” she said, “and that’s kind of what it entails if you want to be a successful mechanical or design engineer.”

In the years since Anderson introduced the partnership with LWTech, he has received overwhelmingly positive feedback about the project. Although some students liken the experience to being taught to swim by being thrown in a pool, they have also come out the other side amazed by what they have accomplished in a short period of time.

“This project gave me a great example of what to expect when I enter into my career and also what will be expected of me,” Yates said. “To me, this project was my first real-life experience of doing an engineering project.

“If you are an engineer looking to gain hands-on experience,” she added, “this class is a great way to do so.”